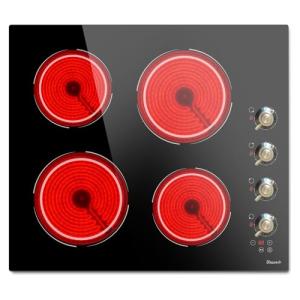

Disaenvir Hobs bring the perfect blend of style and performance to your kitchen. These hobs heat up quickly, giving you a fast and efficient cooking experience. Whether you're sizzling veggies or boiling pasta, you can count on Disaenvir to deliver great results every time.

Disaenvir Hobs

Sleek designs and powerful performance for your kitchen adventures

Product List

Hobs have been a crucial part of human civilization for centuries, serving various purposes from enhancing manufacturing processes to facilitating the creation of intricate designs. Amongst the vast array of hobs available on the market, there exists a category that stands out – the disenviable hobs. This blog post delves into the realm of disenviable hobs, elucidating their characteristics, uses, advantages, and why they might be the perfect solution for your specific needs.

What Are Disenviable Hobs?

Disenviable hobs refer to a distinct classification of hobs designed to improve efficiency, accuracy, and user experience in machining and manufacturing processes. They are primarily used in CNC (Computer Numerical Control) machines and allow for the creation of complex geometries, making them an essential tool in various industries such as automotive, aerospace, and construction.

Table 1: Characteristics of Disenviable Hobs

| Characteristic | Description |

|---|---|

| Material Types | High-speed steel, carbide, or tool steel |

| Cutting Edge Angle | Designed for superior chip removal and retention |

| Tolerance Level | Precision tolerances for accurate machining |

| Application | Suitable for both general and specialized tasks |

| Optimization | Engineered for cutting performance and longevity |

Significance of Disenviable Hobs

With advancements in technology, the role of hobs has significantly evolved. Disenviable hobs offer enhanced capabilities that traditional hobs cannot match. This section explores the significance of disenviable hobs in modern machining.

Efficiency and Productivity

One of the main benefits of using disenviable hobs lies in their efficiency. They are designed to minimize downtime and maximize production output. Factors contributing to their efficiency include:

- Optimized geometries: These hobs are engineered with specific geometrical designs aimed at reducing cutting resistance.

- Advanced materials: The use of high-performance materials ensures durability and resilience under stress.

- Customized features: Many disenviable hobs can be tailored to accommodate specific operational requirements, leading to increased productivity.

Precision and Accuracy

In industries where precision is paramount, disenviable hobs shine. Their design allows for tighter tolerances and greater accuracy in machining, ensuring that every piece produced is consistently uniform. This level of precision is crucial for applications in sectors such as aerospace, where even the slightest deviation can have significant consequences.

Versatility Across Applications

Disenviable hobs are versatile and can be used across various industries. This adaptability makes them an appealing choice for manufacturers looking to invest in tools that can handle diverse tasks. Here’s a list of some common applications:

- Automotive Manufacturing: For producing gears and intricate mechanical components.

- Aerospace Engineering: To create precision parts that require high reliability.

- Tool and Die Making: Essential for the creation of molds and dies used in production.

- Construction Equipment: Ideal for fabricating components designed to withstand harsh conditions.

- Electronics Industry: Used for creating precision parts necessary for electronic devices.

Cost-Effectiveness

While the initial investment in disenviable hobs may be higher than standard hobs, their longevity and reduced maintenance needs can translate to significant cost savings in the long run. Additionally, the performance enhancement often leads to lower operational costs due to increased productivity.

Table 2: Advantages of Disenviable Hobs

| Advantage | Explanation |

|---|---|

| High Performance | Superior cutting capabilities |

| Longer Lifespan | Durable materials reduce wear and tear |

| Customizable | Tailored to meet specific needs |

| Enhanced Precision | Tight tolerances lead to more consistent outputs |

FAQs About Disenviable Hobs

1. What makes disenviable hobs different from other types of hobs?

Disenviable hobs are distinguished by their advanced design features, superior materials, and optimized cutting geometries that enhance efficiency, accuracy, and longevity.

2. How can businesses effectively choose the right disenviable hob?

Consider factors such as the materials to be machined, the complexity of the tasks, required tolerances, and the specific characteristics of hobs. Consulting with manufacturers or industry experts may also provide valuable insights.

3. Are there any maintenance tips for disenviable hobs?

Regular inspections for wear and damage, cleaning after use, and proper storage are crucial to maintaining the performance of disenviable hobs. Adhering to the manufacturer's recommendations is essential.

4. What industries most commonly use disenviable hobs?

They are widely used in the automotive, aerospace, electronics, and construction industries due to their versatility and precision capabilities.

5. Is there a risk of damaging disenviable hobs during use?

While disenviable hobs are designed for durability, improper use, excessive feed rates, or inappropriate machining parameters can lead to damage. It is vital to follow operational guidelines and best practices.

In summary, disenviable hobs represent a vital category of cutting tools that enhance the performance of CNC machines and manufacturing processes. With their ability to improve efficiency, precision, versatility, and cost-effectiveness, it is no wonder that they are becoming an essential tool in various industries.

As manufacturing continues to advance, the demand for high-performance tools like disenviable hobs will only grow. For those looking to elevate their machining capabilities, investing in these high-performance tools may well be the key to achieving unprecedented productivity and precision levels. Whether for a small workshop or a large manufacturing plant, disenviable hobs can transform production processes, making them indispensable in today's competitive landscape.